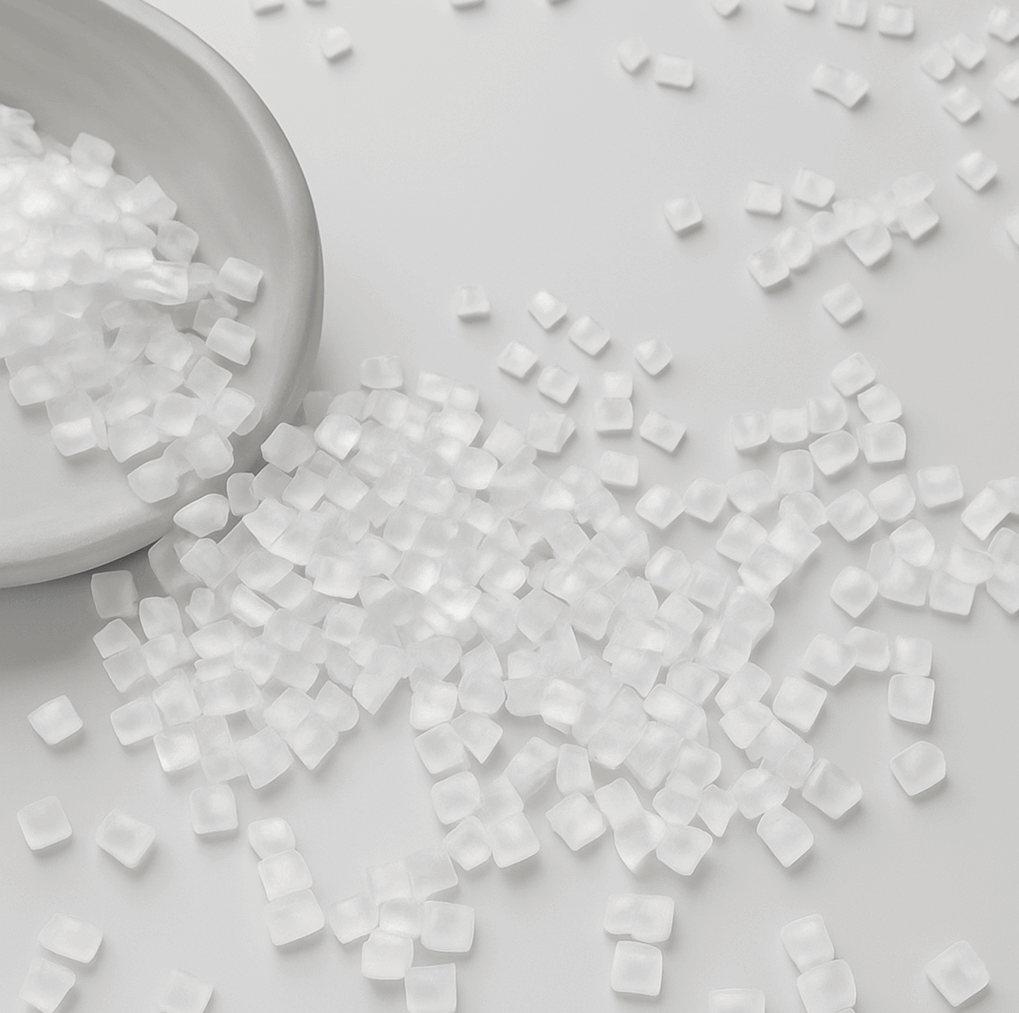

Functional masterbatches added to PE resin to improve film characteristics for packaging and other applications.

Our PE Masterbatch Types:

Anti-blocking agent, slip agent, matting agent, UV stabilizer, antistatic agent, Fluorine-Free Functional Additive

Features

Prevents UV-induced brittleness/cracking.

Delays yellowing, extends outdoor lifespan.

Enhances outdoor durability: Ideal for sun-exposed products.

Customizable to meet specific requirements.

Recommended dosage: 1-5%, adjustable per product requirements.

Features

Suitable for all PE processes: blown film, casting, injection molding, spinning, extrusion.

Prevents oxidative degradation during processing, inhibits molecular chain scission.

Reduces melt strength loss and yellowing.

Customizable to meet specific requirements.

Recommended dosage: 1-2%

Features

Eliminate melt fracture (e.g., sharkskin).

Reduce processing temperature and energy use.

Improve bubble stability and output.

Increase output: Lower melt viscosity, improve extrusion rate.

Reduce die buildup: Prevent accumulation at die lips, extend continuous production time.

Customizable to meet specific requirements.

Recommended dosage:

Initial: 5-10% (20-30 mins for startup/transition).

Normal: 0.5-1%.

Features

Micro-rough surface: Provides lasting anti-blocking.

Easy processing: Low crystallinity, no precipitation.

Uniform dispersion: Evenly distributed in PE films.

https://47.76.241.14:8888/hbgk

Usage Notes:

Dosage: 1-5% (adjust per application).

Excess may reduce transparency/mechanical properties.

Consider synergy with other additives (e.g., antistatic/slip agents).

Features

Controlled migration: Adjustable slip performance.

Low COF: Stable friction reduction.

Good dispersion: More uniform when added as masterbatch.

Customizable to meet specific requirements.

Usage Notes:

Dosage: 0.5-2%. Adjust per application.

Avoid overuse to prevent excessive migration.

Consider synergy with other additives (e.g., antistatic/anti-blocking agents).

Features

No migration: Prevents white powder residue.

Long-lasting slip: Optimizes packaging line efficiency.

High compatibility: Maintains transparency, printability, and heat sealability.

Special formulations available for garment bags.

Recommended dosage: 2-5%